Uses

AM Au-6 Gold Brazing Alloy is used on ferrous, non-ferrous, and super alloys and provides an extremely ductile, high-strength braze joint. AM Au-6 primary applications include brazing of aero-engine components (heat exchangers), and aircraft fuel systems (nozzles and elliptical spray bars). AM Au-6 alloy is also heavily used in electron tubes, vacuum tubes, and wave guides in the electronic industry. Uses also include medical applications, carbide, tube fabrication, and anywhere a critical braze joint is required. AM Au-6 can also be examined after brazing to verify joint integrity and to certify to a Class-A Braze joints (AWS Specification).

Brazing Characteristics

AM Au-6 Gold Brazing Alloy can be successfully brazed onto a wide range of high temperature nickel & iron-based alloys including stainless steels, carbide, and Inconel. A minimum brazing temperature of 1949°F (1065°C) is recommend for furnace and vacuum applications and the use of high-temperature (Black) flux is required when brazing without a protective cover or shielding gas. AM Au-6 is not recommended for joining copper or copper alloys.

Specifications

AM Au-6 conforms to the following specifications: AMS 4786, and American Welding Society (AWS) A5.8 BAu-6/BVAu-6.

Forms Available

Wire, Foil, Atomized powder, Paste, Sheet, and Preformed shapes; rings, washers, discs, shims, specialty shapes. Two dimensional shapes can be Laser-cut and machined with EDM though parts must be cleaned prior to brazing.

Compare With:

- Johnson Mathey: Orobraze 1045

- Lucas Milhaupt: Premabraze 700

- Morgan/Wesgo: Palniro-7

- Prince Izant: Gold Braze 7008

- UNS: P00700

Alloy Details

- Brazing Temperature Range High: 2012 F / 1100 C

- Brazing Temperature Range Low: 1949 F / 1065 C

- Liquidus: 1900 F / 1037 C

- Solidus: 1841 F / 1005 C

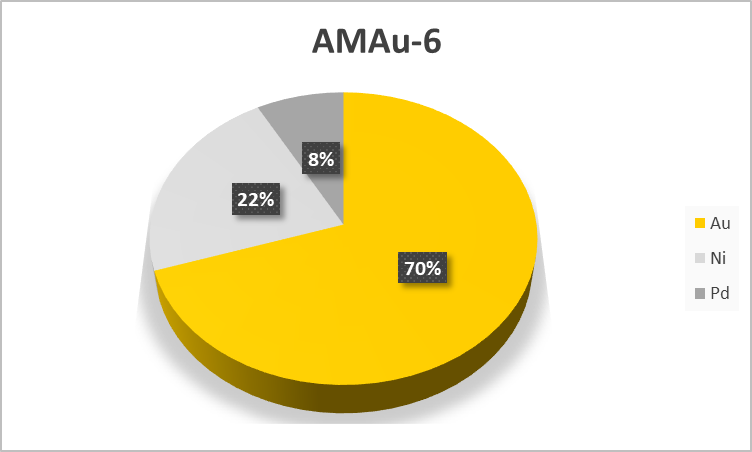

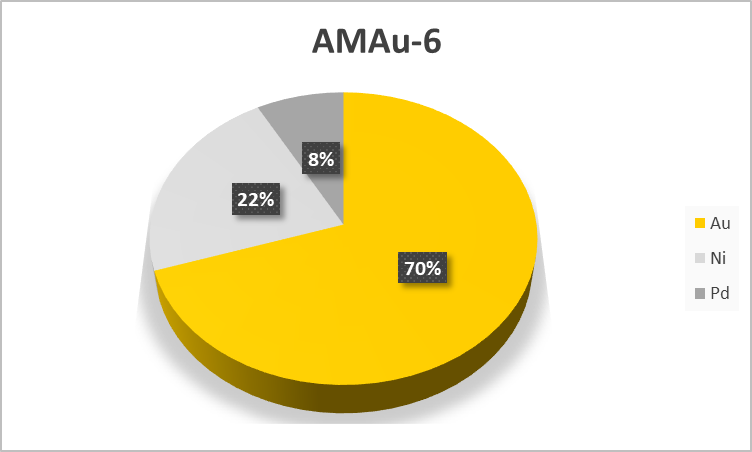

Nominal Composition

- Au: 70%

- Ni: 22%

- Pd: 8%