Uses

AM Pd-25 can be used on all ferrous and non-ferrous alloys and primarily used in vacuum applications within the electronic and for metallized ceramic-to-metal seals. AM Pd-25 has a much lower vapor pressure compared to standard silver base filler metals and offers better strength and wetting ability than BVAg-8.

Brazing Characteristics

The palladium content in AM Pd-25 allows for better wetting than other silver braze alloys especially on Kovar to Mo-Mn Seals. AM Pd-25 has high oxidation and corrosion resistance and creates extremely strong hermetic seals on Kovar, Copper, Nickel, and Metallized Ceramics. The recommended braze interface clearance for AM Pd-25 is 0.001 - 0.002” Inches.

Specifications

AM Pd-25 conforms to American Welding Society (AWS) A5.8/A5.8M BVAg-32 Grade 1 and 2

Forms Available

Wire, Foil, Atomized powder, Paste, Sheet, and Preformed shapes; rings, washers, discs, shims, specialty shapes. Two dimensional shapes can be Laser-cut and/or machined with EDM though parts must be cleaned prior to brazing.

Alloy Details

- Brazing Temperature Range High: 1752 F / 956 C

- Brazing Temperature Range Low: 1702 F / 928 C

- Liquidus: 1742 F / 950 C

- Solidus: 1652 F / 900 C

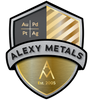

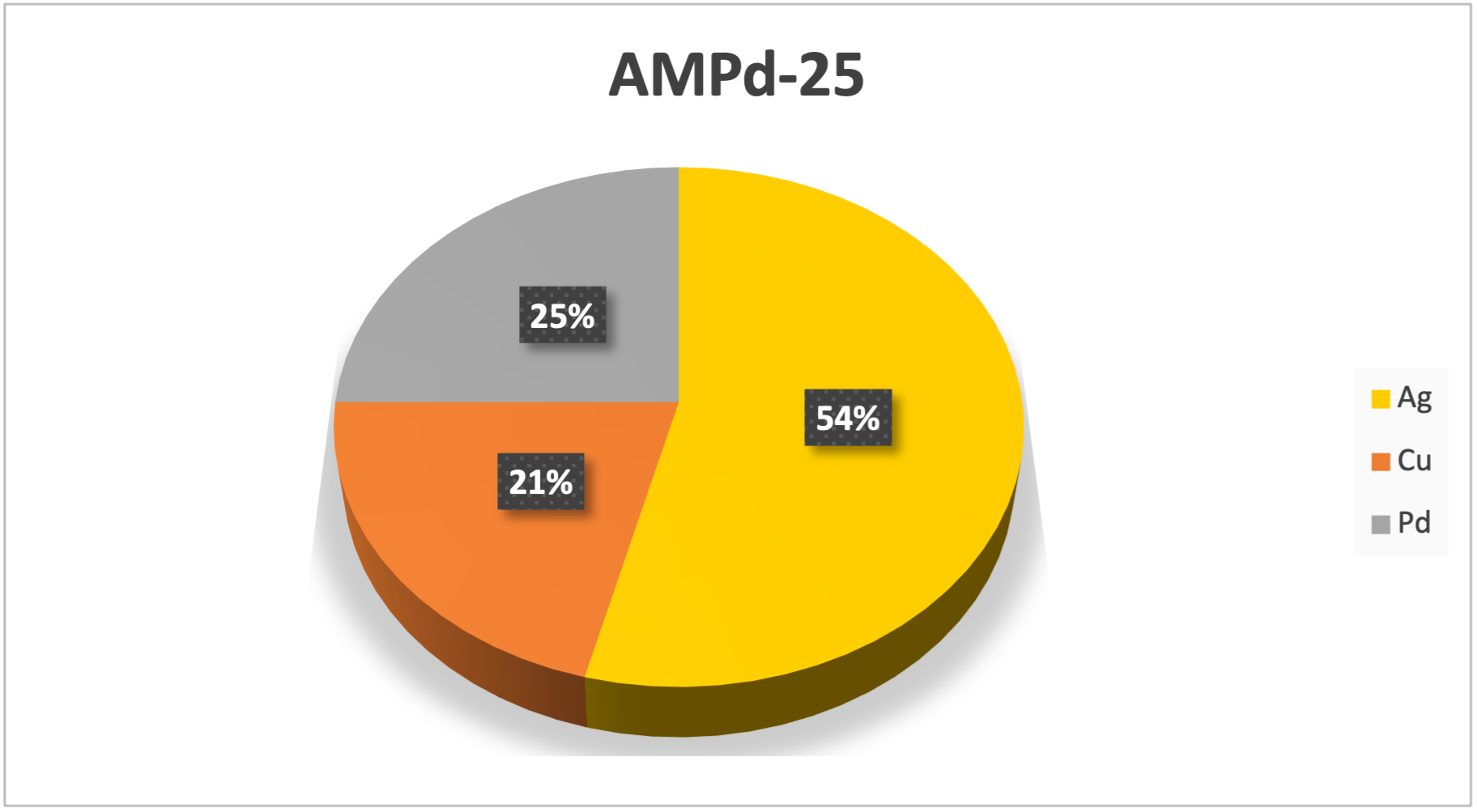

Composition

- Ag: 54%

- Cu: 21%

- Pd: 25%

Compare With

- AWS: BVAg-32

- P&I: PAL 25

- Wesgo: PALCUSIL 25